Clare and I watch the fireworks listening to her friend Bill sing the national anthem.

Here’s the video of him singing it:

Clare and I watch the fireworks listening to her friend Bill sing the national anthem.

Here’s the video of him singing it:

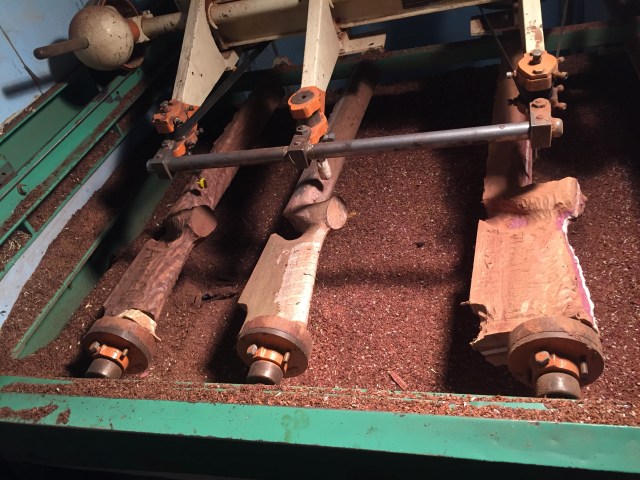

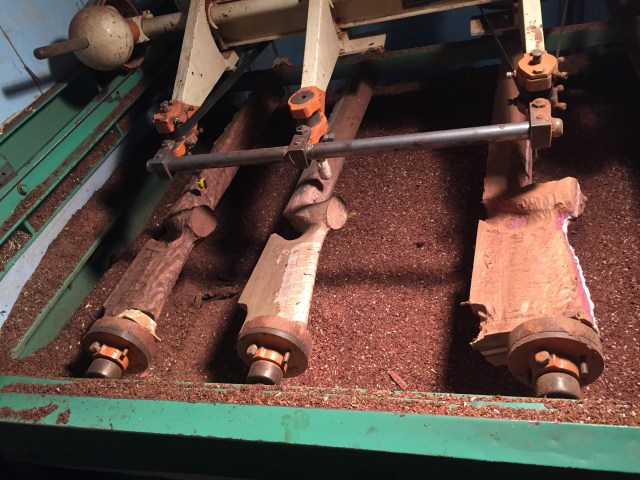

These will be unique because they arelonger than standard length. The pattern has been modified. Notice the difference in the weight of the two woods.

This was very much appreciated and really raised my spirits to know that you are all thinking of me. Treatments are going well and I will be back at the matches soon! ~ Doan

Check out the inlay in the wood. If you know or remember Morse code, you will be able to read the initials.

A couple years ago a similar stock for another junior… and this stock is built in the same theme, but not identical.

Some of the inletting has been blanked out, so that it can be a surprise for it’s owner.

The owner of this was a winner of a certificate at the F-Class Nationals.

One will be a 2000 Anschutz prone stock and the other will be a combination Palma and F/TR stock with a Stolle Panda action.

Hi Everyone.

I’ve been slowed down for the last couple weeks. Albuquerque was hit with one heck of cold session. We all got it.

We’ll be back to our normal posting schedule soon.

Question.

Anyone going to the Berger Match that needs a roommate? Let me know.

Thanks,

Doan.

Humbucker pickup installed with wiring and volume control. The neck has been fitted, and the owner picked up the guitar, and he will install the strings and tune it. Concert to follow.

1967 Rickman Triumph Metisse Motorcycle – Rare

1967 Rickman Triumph Metisse Motorcycle – RareIt was built in April 1967 – this was the first year that they went into production on the T100A.

There were 26 T100A’s made in 1967. 46 in 1968. 59 in 1969. 26 in 1970. 9 in 1971 for a total of 166

My frame number is 1083 and it’s a Mark IV. This was the second by number of the first shipment.

I know that the bike was raced here in the States in the Summer of ’67. I believe it was shipped to FAD Engineering in Syracuse, NY. My guess is that it has to be one of the first ones built in the States. I bought it in 1968/1969.. and continued to race it until 1975.

Before I bought it, it was raced by a man with the nickname, “Frenchie”.

When I bought the bike the name on the registration was Bill Humes.

I took the original engine out in 1969 and replaced it with another T100.

The engine that is in the bike was built by Ray Beebe, from Central NY Cycle (Triumph Dealership). The head that is on the engine is called a Baltimore Head. These specific heads were developed in 1965 for Gary Nixon for his road racers and flat track bikes. These were sold under the Tricor name. They used a slightly higher compression and slightly larger valves. When Nixon won the Daytona 200, Triumph renamed the 500cc the Daytona.

I still have the original fender and the two number plates.

Orginal motor 61 Triumph with distributor, converted to ET. If the ET was not spot on it wouldn’t function correctly. This is why I changed the engine in 69/70.

In 1968, I added the removable lights, so I could take them off for racing.

Asking $19,900.00

~DOAN

This type of wood is very time consuming because there are very hard and very soft parts – i.e. the fiddleback and quilting. It requires hand sanding sanding with a pad to eliminate high and low spots and to get a fine finish.

Handcrafted, old fashioned, time-honored stock duplicating can produce a superior product to a mass-produced stock from a CNC machine at far less cost. Custom stock duplicating using manual duplication can produce a stock that is as precision as any CNC produced item. If I used an expensive CNC machine, I would have to raise the cost considerably, and I don’t feel that the product would be superior. Why choose a mass-produced assembly line stock when you can have a custom, one-of-a-kind custom design?

The stock on the left is a presentation grade Claro walnut stock. The one on the right is Curly Koa, Purple Heart, and Maple laminate.

This stock is a duplicate of the owner’s high power Palma rifle. He wanted the same look and configuration on both stocks.

These are some of the during construction photos. You can see some of the bedding process, note that this is using a bedding block which allows for exchanging 2000 actions.

I’ve got the body and the neck cut out. The nut has been replaced with brass. Frets have been leveled. And the pickup has been cut out. Next, I will do the wiring and the controls. After that the shape and finish.

I couldn’t bear to take a picture of this when the stock was broken into two pieces, but here is the fix in progress. Was returned to me after it fell off a workbench, and I didn’t know if it could be repaired. I’m giving it a try. This is after a couple of days work.

The link to the completed stock before this unfortunate accident happened. https://doantrevor.com/2015/08/12/2000-anschutz-mango-stock/